Forget Vinyl. Forget the Cloud. In the Future We’ll Listen to Music on UV-Cured 3D-Printed Resin

Musicians, developers, and inventors prove that there’s more to records than vinyl

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/fc/65/fc65876a-21b9-4f0c-8d9b-e9701a6cc370/record-cutting-machine.jpg)

The first time I heard the White Stripes, I remember thinking, "This is high quality rock and roll. Pure and simple." There's something undeniably authentic about the unabashed, heart-on-sleeve music of the White Stripes. It fits seamlessly into the continuum of music history, bridging the past with the present, somehow sounding like both.

When Jack White started the label Third Man Records in 2009, he intended "to bring a spontaneous and tangible aesthetic back into the record business." What does that mean? Well, for one thing, it means making actual records. Like the music of the White Stripes, Third Man's vinyl records combine tradition and innovation.

In June, White released Lazaretto, an innovative 12-inch vinyl record that looks like a standard LP, but has been designed with a few tricks up its sleeve, so to speak. A few of the record's features: "dual grooves" on the opening track of side two mean that either an acoustic or electric version of the song will play depending on where the needle is dropped, holographic angles hand-carved into the surface of the vinyl spin with the record, and two hidden songs are concealed beneath the labels, with one playing at 78 RPM and the other at 45 RPM, making Lazaretto possibly the first three-speed record ever pressed.

Lazaretto proves what a lot of people already knew: in the face of tapes, CDs, MP3s, and the omnipresent cloud, vinyl records aren't just surviving, they're thriving. New fabrication techniques and digital technologies are expanding the possibilities of the analog medium.

On the DIY website Instructables, developer and audiophile Amanda Ghassaei has posted experiments in using 3D printing and laser cutting to create custom records. Her instructable teaches other audiophiles to transform audio files into 33 RPM resin records using a very high resolution 3D printer that creates objects layer by very thin layer.

The 3D printer isn't as precise as a vinyl cutting machine, and the sound quality leaves a lot to be desired, but among the clicking, hissing and scratching on the prototype 3D record, Nirvana's "Smells Like Teen Spirit" is unmistakable. Unless you're making a record for an old Fisher Price toy record player, desktop record-pressing isn't quite practical yet, but it is pretty darn cool.

Ghassaei also created a record by laser cutting the grooves onto plastic, paper and, incredibly, wood. The sound is similar to the 3D printed records, but the maple record is just beautiful. And there’s something almost poetic about carving rings into a tree. I wonder though, what would it sound like if one “played” a very thin slice of a tree, dropping the needle on the grooves created by tree rings? What is the sound of nature? I’m reminded of an essay by Rainer Maria Rilke (1875-1926), “Primal Sound,” in which he waxed poetic on a similar notion, wondering what would happen if the gramophone needle was dropped on natural and biological grooves such as the coronal sutures on a human skull:

What would happen? A sound would necessarily result, a series of sounds, music...Feelings—which? Incredulity, timidity, fear, awe—which of all the feelings here possible prevents me from suggesting a name for the primal sound which would then make its appearance in the world?

Rilke imagined the entire world transforming into sound.

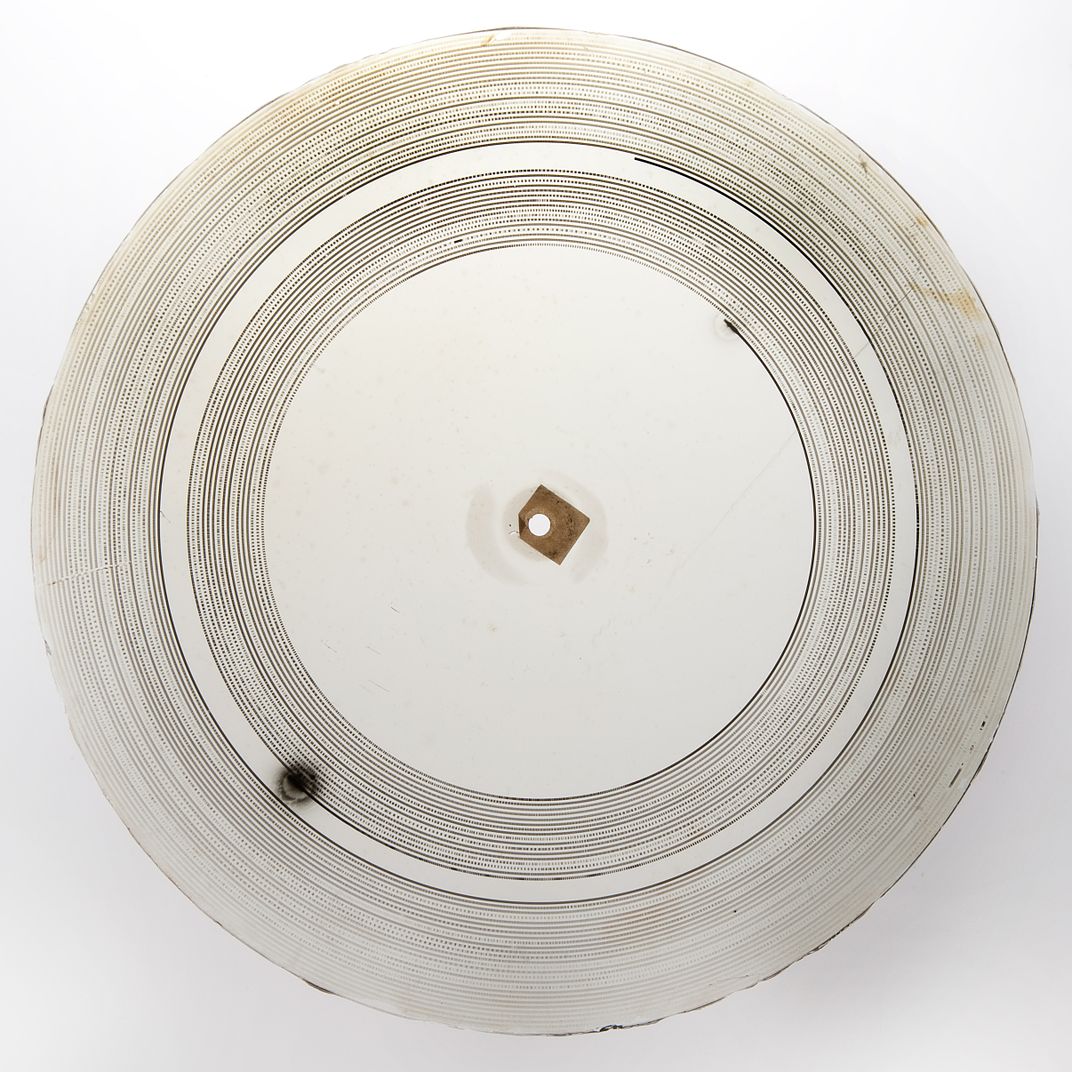

Experimenting with records is a practice that dates back as far as recording itself. Before vinyl became the standard in the 1930s, records were made from a shellac; but before shellac, a variety of materials were tested as inventors searched for a medium to hold sound. Among the 400 early experimental audio recordings in the collection of the National Museum of American History are records made from brass, beeswax, rubber and glass.

These early recordings have been in the Smithsonian's collection for a very long time, but it wasn't until 2011, when researchers were able to play them using a recently developed, noninvasive sound recovery process developed at Lawrence Berkeley National Laboratory.

When one of these glass records—produced by Alexander Graham Bell and his associates in, 1885—is played, among the clicking, hissing and scratching, a man's voice can be heard saying the date and repeating "Mary had a little lamb," perhaps in homage to the first audio record Thomas Edison made in 1877. The fuzzy audio is barely decipherable. It actually sounds a lot like the 3D printed records. And I have to imagine that the joy felt by inventors embedding sound into a glass disc is the same joy felt by today’s developers and hobbyists who embed music onto UV-cured 3D-printed resin.

Forget record store romanticism. Whether or not you believe that listening to music on vinyl somehow constitutes a more authentic experience than listening to digital recordings, there’s something undeniably visceral about physically manifesting sound, about actually making music. Modern musicians, developers, engineers and inventors using new technologies to make beautiful music together are proving that, when it comes to vinyl, we’ve barely scratched the surface.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Jimmy-Stamp-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Jimmy-Stamp-240.jpg)