Scientists Make Food From Bacteria, Water, Electricity, and a Whole Lot of Patience

You may have heard that Finnish scientists had made food from electricity, but the truth is more complicated

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/b0/1e/b01ea4c5-4d00-43cb-91f7-52069ec61bc9/img_1689_edit.jpg)

Take water, carbon dioxide and microbes, add a jolt of electricity and a dash of time, and voila: protein. This recipe comes from Finnish scientists, who say they’ve developed a technique for making food nearly out of thin air.

Well, sort of. The food is a powder made from a type of bacteria that lives on hydrogen. That's not exactly out of thin air, and right now it takes two weeks to produce a single gram. Hardly the revolution you might have read about in the headlines.

But the researchers say that—if the production process could be scaled up—it could be a cheap way to feed livestock, freeing up land to grow food for humans, or plant carbon-dioxide-sucking trees. Further down the road, it could even be a meat alternative for humans, though it likely wouldn't be an easy sell on menus.

“It’s not so much different than making beer, but in making beer of course you use sugar as the raw material but in this case we use hydrogen,” says senior scientist Juha-Pekka Pitkänen of the VTT Technical Research Centre of Finland, a state-controlled scientific research center.

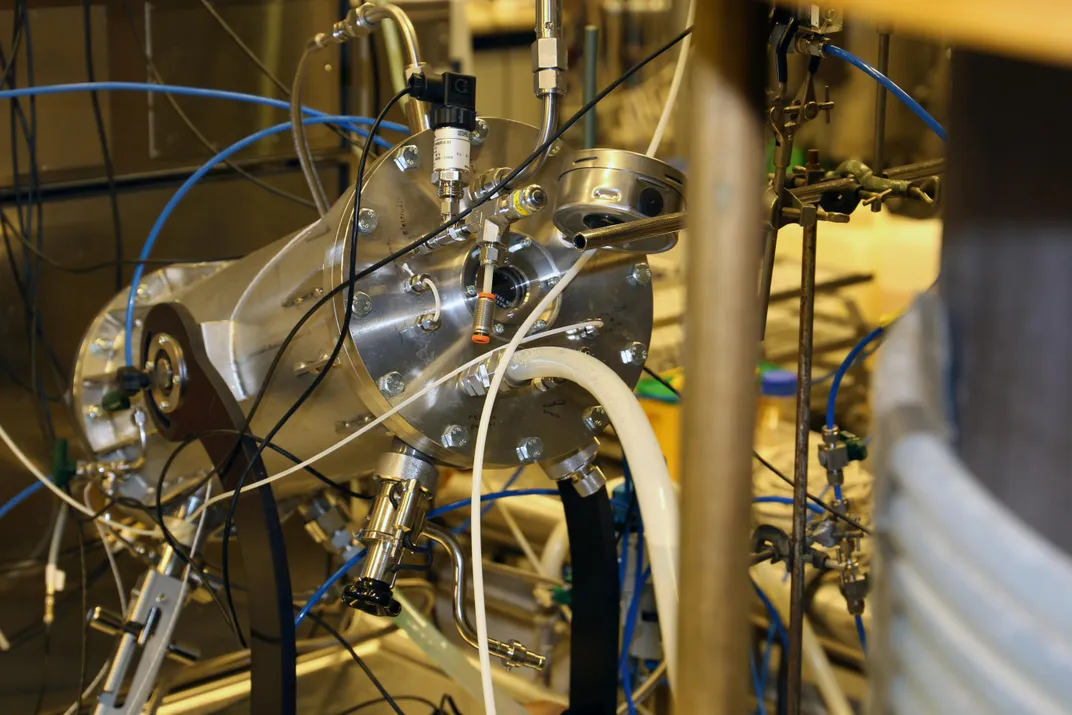

By this Pitkänen means both processes begin with feeding a single-celled organism to produce an edible (or drinkable) product. The protein creation process starts with hydrogen-oxidizing bacteria, which use hydrogen as their energy source. The scientists put the bacteria in a coffee-cup-sized bioreactor along with water and an electric water splitter. The splitter splits water into hydrogen and oxygen; the bacteria eats the hydrogen. Combined with carbon from the atmosphere, and a small amount of added “fertilizers” (ammonia, phosphorous and various inorganic salts), the end product is a dry bacteria powder that is about 50 percent protein, 25 percent carbohydrate, and 25 percent fats and nucleic acids. It can be used as is, or processed more to make pure protein, researchers say. Right now it has very little taste and a texture similar to dry yeast; the texture can also be altered if slightly different microbes are used.

The next step for researchers is to refine the process to produce protein on a much larger scale. This will involve building new reactors, improving efficiency, and adjusting energy levels to help the bacteria grow as quickly as possible.

If this scaling-up is successful, it could create a food production system that doesn’t rely on traditional agricultural processes. It also has the potential to be highly sustainable – researchers say their estimates show it could be significantly more energy efficient than photosynthesis in terms of the amount of energy input necessary to produce a given amount of food.

“We don’t require arable land,” says Pitkänen. “We can do this in a desert environment or in other places unsuitable for agriculture.”

The work is part of an ambitious project backed by the Finnish government to reduce carbon emissions through innovation. Pitkänen and his team’s work was a joint effort between the VTT Technical Research Centre and Lappeenranta University of Technology.

The first major goal of the project is to produce the protein on a large enough scale to use as animal feed. That way, land currently used to grow feed crops like corn and hay could be used for more sustainable purposes, such as planting trees. This could be especially important in places where valuable forests are being clear cut to make way for cattle, such as in the Brazilian rainforest. The scientists envision the protein being produced in a shipping container-like building at a farm, using as small a footprint as possible.

Down the road, the scientists hope the protein could be used as an environmentally friendly protein source for humans. They envision a substance similar to tofu or Quorn, a meat substitute made from a fungal protein grown through fermentation. In theory, mobile protein production facilities could even be brought to areas experiencing famine, offering a cheap, healthy food source for starving people. Much further down the line, researchers envision countertop protein reactors for at-home use.

Creating food from single-celled organisms is not new. Humans have been eating some single-celled proteins (SCPs) – the blue-green algae spirulina, for example – for hundreds or thousands of years. But as the population grows and the impacts of agriculture on the environment increase, producing SCPs from sources including bacteria, yeast and fungi has become a subject of intensive study. A recent review of the research from New Zealand scientists suggests using SCPs as human food has both advantages and disadvantages. In order to be a useful food product, a given SCP must be genetically stable, highly productive and resistant to subtle changes in pH and other environmental conditions. It’s also difficult to sell novel protein sources to the public, the researchers concluded. Other research suggests that SCPs are a lesser-quality protein source than foods like meat, and have potential to be allergenic.

But if this new product proves successful, it could have advantages over other SCPs such as spirulina because it can grow with so little equipment in almost any environment.

Despite these potential barriers, Pitkänen and his colleagues are optimistic. They hope to have a product ready for market in a decade or so.

“It would tick so many boxes related to sustainability,” Pitkänen says. The human population is increasing, CO2 levels are increasing. So it could really solve big issues.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/matchar.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/matchar.png)