A Big Bet on How to Store Energy, Cheaply

Tech innovators are hoping they can store energy more cost-effectively with mechanical systems that use the most basic materials: air, water, and steel

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/fd/b4/fdb476eb-c0e9-4e0f-8417-83c9bd6ef66d/icaes_sept_2013_sm2edit.jpg)

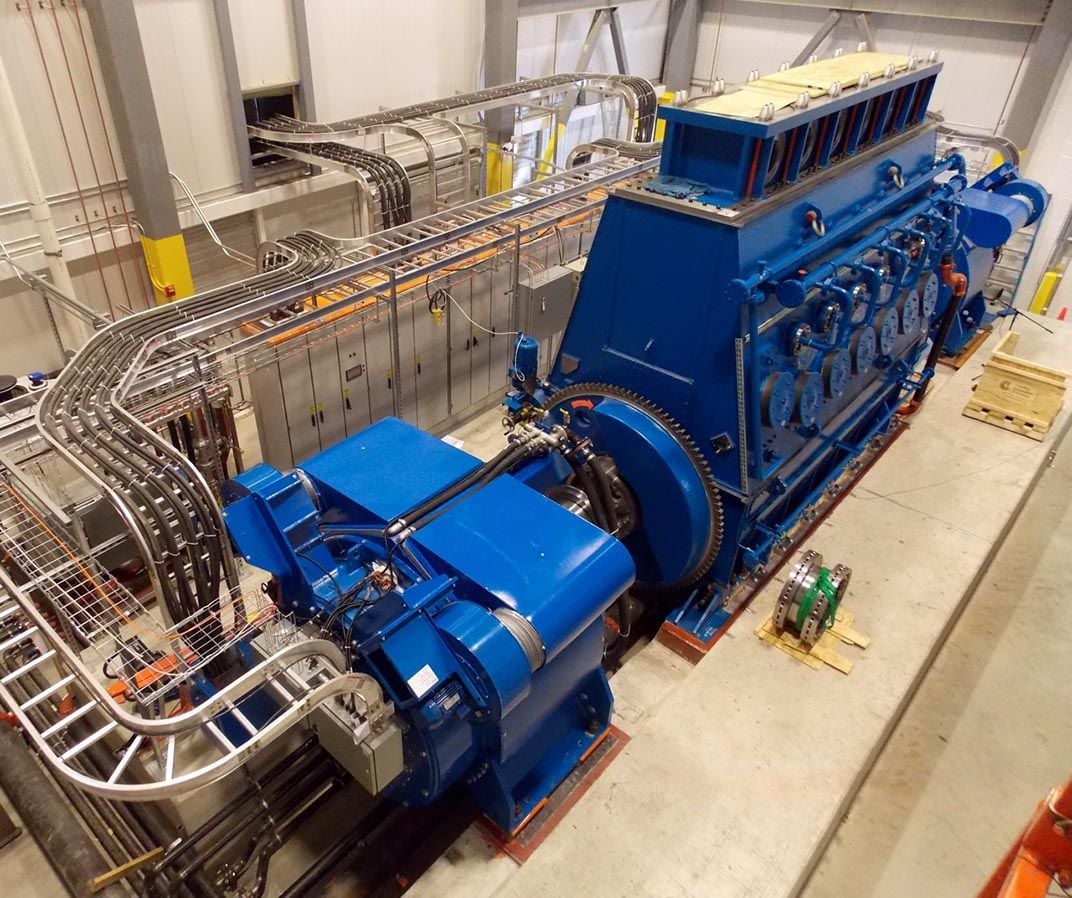

At the back of a warehouse-size workshop, about a dozen engineers in hardhats are building a giant blue machine. Six cylinders, each taller than a person, and a thicket of tubes, pipes and valves extend upwards from a marine diesel engine encircled by a three-story scaffold.

Conceived by startup SustainX in Seabrook, New Hampshire, the machine is designed to store energy by compressing air. An electric motor turns the engine’s crankshaft to drive pistons in the cylinders above. The pistons squeeze a mixture of air and foamy water and pump the pressurized air into large steel tanks where it can be held like a coiled-up spring. When an electric utility needs power, the tanks will be uncapped, allowing the air to rush out, power the engine, and generate electricity for the utility’s customers.

The stakes are high. If a company such as SustainX can deliver a system that can cheaply store energy for even a few hours at a time, it would turn wind and solar into dependable power providers, more like fossil fuel plants. Fluctuations in wind and solar output could be smoothed out and excess power from nighttime winds, for instance, could be dispatched later when demand is higher.

SustainX's machine and others like it are at the leading edge of a technology race in energy storage. The company’s work, backed by more than $30 million in private and government funds, represents a bet that clever engineers using cheap and easily available materials like air and water will beat out the legions of scientists who are chasing a breakthrough in batteries.

Energy storage attracts so much attention because a breakthrough in cost and performance could make the electric grid cleaner and more reliable. Every day, utilities operate a constant balancing act: to ensure reliable service, the amount of power generated at power plants needs to match what’s being consumed at homes and businesses. If there’s a spike in demand from air conditioners on a hot summer day, for example, power plants need to crank out more electricity and dial it back down when demand subsides at night.

Energy storage acts as a reserve, or an energy bank account. During times of peak demand, storage can deliver power in the place of “peaker” fossil fuel plants. The technology can firm up the variable output from wind and solar farms or augment the capacity of maxed-out substations that deliver power to local neighborhoods. When placed in or near buildings, energy storage can provide backup during a power outage. Many of these applications, though, require a device that can provide power for a few hours or perhaps half a day. And it has to be done safely and at low cost.

For multi-hour storage, there are compelling reasons to pursue mechanical storage systems over electrochemical batteries, say industry executives. Batteries require more expensive materials, such as lithium or cobalt, which can be subject to supply constraints. Unlike a mechanical system, a rechargeable battery's storage capacity decreases over time, as most laptop users have experienced.

Then there’s the pace of innovation. In general, the pace of development in battery research is slow—measured in years, rather than months—and performance improvements are often incremental. Also, making new types of batteries in large volume requires big upfront investments in factories. An innovative mechanical system, by contrast, could be assembled from slightly modified engines, industrial gas tanks, and other equipment that is already well understood and produced at large scale.

"It's a sort of [a] systems integration challenge, rather than having to invent and build a particular device to make it all work," says Gareth Brett, the CEO of London-based Highview Power Storage, which uses liquefied air—air pressurized and cooled until it turns liquid—to store energy on the grid. “Our intellectual property is in how the system is engineered and brought together in a way that is efficient and low cost.”

When it comes to storing electricity for use on the power grid, pump storage hydropower is considered the gold standard—a relatively cheap technology that has delivered energy in the United States for more than 80 years. As the name implies, water is pumped uphill to a reservoir when electricity demand is low, and released when needed to generate electricity through a hydroelectric turbine. Pumped hydro stations can deliver big bursts of power for several hours, allowing grid operators to fill gaps in electricity supply without having to tap fossil fuel-burning power plants. They’re mostly limited, however, to mountainous terrain, which provides the elevation gain needed between reservoirs, and environmental reviews take many years.

The other proven, low-cost bulk storage method is compressed air energy storage, or CAES, in which compressors pump air into underground caverns. When power is needed, pressurized air is released and heated by burning natural gas. That air is then blasted into a turbine to generate electricity. There are two geological compressed air energy storage plants in the world, including one opened in Germany in 1978 and another opened in Alabama in 1991. Both units still operate and are considered successful. But no others have been built because it’s difficult to find locations with a suitable geological formation and to finance these projects. A third plant could join their ranks in Texas, with plans calling for a $200 million project to store up to 317 megawatts—comparable to the output of a medium-sized power plant.

Innovators at energy startups have drawn inspiration from both of these techniques, branching off in a variety of directions. SustainX and Berkeley, California-based LightSail Energy propose to compress air for storage, but keep it in above-ground tanks, which means they aren't limited to locations with underground caverns. Newton, Massachusetts-based General Compression has developed a compressed air storage system that attaches directly to wind turbines.

The key difference from traditional CAES in these approaches, called isothermal compressed air energy storage, is that no fuel needs to be burned on site. Instead, these second-generation CAES companies capture and reuse the heat that’s generated when air is put under high pressure. LightSail Energy intends to spray a fine mist of water as air is compressed and store that hot water until later. When pressurized air is released to generate electricity, the hot water, rather than a natural gas burner, heats the air through a heat exchanger.

A potentially cheaper CAES approach is storing compressed air in fabric bags underwater. When storing air in steel tanks, the steel needs to be thick enough to contain high-pressure air. But water pressure could do the job instead—for free. While working at a solar startup, former rocket engineer Scott Frazier foresaw the need for an inexpensive storage system that could be placed nearly anywhere. And in 2010, he co-founded a company, Bright Energy Storage Technologies, to pursue the idea of storing compressed air in large bladders anchored to the ocean floor or the bottom of freshwater reservoirs.

"If I have a tank above ground, you have to pay more for higher pressure. The more air I pump in, the more steel I need—it's pretty linear," says Frazier. The company’s first prototype, built for the U.S. Navy in Hawaii, will use a modified truck engine to pressurize air in tanks above ground. If the mechanics of that machine prove practical, the company and the Navy plan to build a second prototype that stores air underwater.

Even simpler bulk storage designs would harness gravity much the way pumped hydro stations do. Advanced Rail Energy Storage, based in Santa Barbara, California, is seeking to build projects where the energy from solar or wind farms would push a train of railcars up a hill when there’s low demand for energy on the grid. When power is needed most, the rail cars would travel downhill and generate power. The electric traction motors that push the cars uphill run in reverse when going downhill and operate as generators, the same way a hybrid car charges a battery during braking. In a similar concept, EnergyCache, founded by an MIT mechanical engineer and funded by Bill Gates, built a demonstration storage system where gravel is transported up and downhill using modified ski lift equipment.

In the decades-old area of pumped hydro storage, there are novel ideas as well, including storing water in aquifers or siting plants at the ocean, as one company in Japan has already done. These approaches use the same basic configuration—an artificial reservoir at a high location next to a lower reservoir—but could potentially be built in more locations. Most ambitious are proposals to build an “energy island” in the North Sea off the Dutch or Belgian coasts. The idea is to build an artificial island with a reservoir and use the excess energy generated by wind turbines at low-demand times to pump water for storage.

All these innovations start with cheap materials but eventually run into the same engineering challenge: efficiency. If a lot of energy is lost converting electricity to compressed air or stored water and back again, the costs go up. In this area, batteries compete very well: some types are more than 90 percent efficient in charging and discharging.

The trick, then, for mechanical storage, is to bump up efficiency in as many ways as possible. With air storage, that often means making better use of heat. While isothermal CAES developers like LightSail capture heat generated from compressing air, other innovators are harvesting heat from outside sources that would otherwise go to waste. At its demo project near London, Highview Power Storage pipes in waste heat from a nearby power plant when converting stored liquid air to high-pressure gas, which turns a turbine to make electricity. Using a variety of techniques, even storing cold air in gravel to aid the cooling process, Highview Power Storage can get energy conversion efficiency to over 70 percent, he says.

A mechanical system can’t match the best batteries on efficiency, but that misses the point, says Richard Brody, the former vice president of business development at SustainX. More important, particularly for multiple-hour storage applications, is the relatively low upfront cost and the fact that mechanical systems can run for decades without losing storage capacity. A well tuned machine with basic ingredients—steel, air, water, and gravel—won’t degrade the way the chemical compounds in battery electrodes do over time, mechanical storage advocates say. “We haven’t seen any electrochemical [battery] technology that can do what we can do at the scale and system life we’re talking about,” says Brody. “We think it’s impractical to do megawatt-scale stuff with any of these cell-based battery systems.”

Given the potential for widespread energy storage on the grid, approaches using low-cost materials continue to attract serious attention. In addition to a number of startups, many researchers are working on compressed or liquefied air. The University of Birmingham in the United Kingdom, for instance, created a research center for cryogenic energy storage and a consortium led by German utility RWE has committed 40 million Euros ($53 million) over three and a half years to develop a high-efficiency CAES system that will store heat from the compression process in large thermos-like vessels filled with ceramic material.

This branch of storage technology could aid transportation as well. Engineering company Ricardo has two projects to explore how liquefied air can improve the efficiency of internal combustion engines. Peugeot Citroen, among other automakers, is pursuing a method to use a compressed air storage tank to effectively act as a battery would in a hybrid passenger car. Much of the appeal is the ready availability of parts and infrastructure, says Dr. Andrew Atkins, chief engineer of technology at Ricardo. “You don’t have any supply chain issues,” he says. “After all, air is all about us.”