How Candy Canes Are Made by Hand

Hand made sweets are still crafted in specialty shops

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c0/ff/c0ff18ae-f715-40d7-b2c4-c2ad07c71b08/42-34757586.jpg)

Nothing gets the nostalgia pumping like the holidays, when traditions are revived, and we sing songs full of old-timey phrases. ("Don we now our gay apparel" is not a common phrase during other seasons.) And nothing is quite so sweetly quaint as methods for making old-fashioned candy.

Lofty Pursuits in Tallahassee, Fla., keeps alive the traditions of Victorian-style candy making and the experience of a classic ice cream parlor and soda shop. They also post videos, such as this one that details how they hand-make candy canes during the holidays (via kottke.org).

The entire video is fascinating, but it’s also nearly 10 minutes long. Here are some of the key steps:

Red dye, mixed with a touch of blue, gives the melted sugar a burgundy color. It’s 300 degrees to start, but then it’s poured on a 130-year-old table that helps the sugar cool enough to become moldable. Once the candy has cooled to a workable temperature, the candy makers move it to a warming table that keeps it warm enough to stretch. The un-dyed sugar goes from amber-colored to white as the stretching incorporates air.

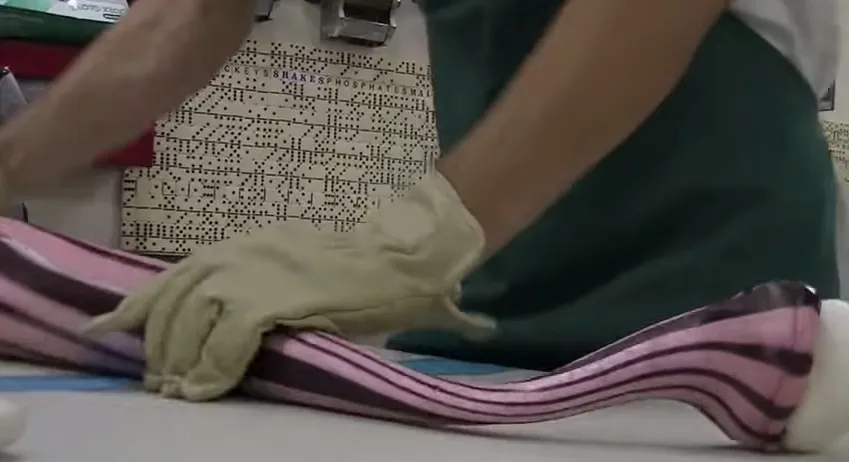

Some burgundy mixed with white candy creates pink for the stripes. The center of the cane will be white, which makes the colors on top pop, one candy maker explains. The white core is rolled up in the stripes.

The eight-pound candy log is then stretched out into a rope.

Each cane is twisted and cut off the end of the rope.

The candies are left to cool.

If you can’t get enough of this hand-stretched sugar, watch the Lofty Pursuits crafters create flag image candy or a giant candy cane for an elephant.