The Hyperloop Will Be Only the Latest Innovation That’s Pretty Much a Series of Tubes

The idea of using pneumatics to send objects has been around for ages. But people?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/30/f2/30f29dc1-beab-427b-97c9-ce8bb79eb035/julaug2015_b01_clivethompsonhyperloop_webresize.jpg)

Let’s say you’re in San Francisco, and suddenly decide, “Hey, let’s have dinner at Spago in L.A. tonight!” The fastest way to get there is a 1.5-hour flight, which isn’t exactly convenient.

Unless Dirk Ahlborn has his way—in which case you’ll be able to make the trip in a mere 36 minutes.

Ahlborn is part of a consortium trying to build the world’s first “hyperloop,” a radically speedy new form of land-based transportation. To ride a hyperloop, you’d show up at a San Francisco station, and then board a windowless, bullet-shaped capsule. The capsule would sit inside a long tube that stretches from one city to another, raised a few stories aboveground on pylons. A huge air compressor mounted on the capsule would suck air from in front of the vehicle and squirt it out behind—turning the capsule into a rocket. Hovering on a cushion of air (or possibly suspended magnetically) and racing through a vacuum, the hyperloop would face very little friction, so you’d shoot along at a dizzying 760 miles per hour.

The hyperloop was originally proposed in 2012 by the high-tech entrepreneur Elon Musk as a way to kick-start a new generation of superfast land transit. But by late 2014, Ahlborn—a German-born entrepreneur who co-founded a crowdfunding site for startups—seized on the idea. He assembled a group of 300 engineers willing to work on the concept, forming a company called Hyperloop Transportation Technologies. They plan to break ground next year on a five-mile-long proof of concept. And they’re not the only ones: Another group—the nearly identically named Hyperloop Technologies—is composed of several high-tech millionaires and has raised $8.5 million to develop the technology for transporting cargo. And in January, Musk tweeted that he too plans to build a test hyperloop track for companies and students to use, most likely in Texas.

If it works, proponents claim, hyperloops could transform transportation. You could order a product from a factory in Detroit and have it arrive in New York the same morning. The entire country could be connected by tubes, squirting humans and goods around at lightning speed.

“It’s doable,” Ahlborn tells me. “It’s feasible. We’re going to build something that people use every day, several times a day.”

If so, it’ll be the triumphant return of a technology that flourished at the outset of the 20th century: the pneumatic tube. One hundred years ago, tubes used blasts of air to change the way we communicate and do business—creating an Internet not of bits, but of matter.

The idea of using air to push things along is, it turns out, quite old. In Greek antiquity, Hero of Alexandria proposed several devices that used compressed air, steam and liquids to propel quixotic machines, such as “A Jet of Steam Supporting a Sphere.” (“Pneumatic” comes from the Greek pneumatikos, for “of the breath.”) By the mid-19th-century industrial revolution, engineers were becoming even more adept at pneumatics. “They were trained on the steam engine. That was the big technology of the age,” says Steven Lubar, a professor of American studies at Brown University. “And they’re really good at making compressed air.”

But what really launched the pneumatic tube was the telegraph. Telegraphs were increasingly important for stock market communications, but they had a “last mile” problem. Telegraphs would arrive at the central telegraph office in a city, whereupon messengers would bring them to financial firms in horse-drawn carts—ponderously slow, especially since city streets were increasingly jammed with traffic. All the delightful, lightning-fast advantages of telegraphy ground to a halt when messages had to move overground.

In 1853, a British engineer named J. Latimer Clark proposed a solution: Why not connect the financial firms directly to the telegraph office using pneumatic tubes? When financial messages arrived at the London telegraph office, they’d be placed in a container—such as a cylinder made of gutta-percha, an early form of latex—and loaded into a 1.5-inch-wide tube. A steam engine pump would create a vacuum in the tube, so that any payload placed inside would be sucked rapidly along to its destination. (Later tubes inverted the flow: They’d use steam-engine-driven pumps to blow air into the tubes, pushing the canisters along.)

Financiers loved it. Not only were the tubes fast, but they were high bandwidth. A telegraph wire could transmit only one message at a time, but a pneumatic-tube canister could be jammed full of dozens of messages at once. Indeed, one analysis found that a three-inch-wide tube could transmit messages “equivalent to seven telegraph wires and fourteen operators working flat out,” as Tom Standage notes in The Victorian Internet. As a bonus, tube-sent messages could be sealed in envelopes, keeping them from prying eyes—not something you could say of a telegraph message, which was always read by the telegraph operator.

“It was the high-frequency trading technology of the day,” says Molly Steenson, an assistant professor of journalism at the University of Wisconsin in Madison. Tube systems quickly emerged for financial centers around the world. Soon the Paris stock exchange had a dozen station nodes, and London’s system had grown to 74 miles of tubes. “Tubes go where commerce goes,” Steenson says.

In the U.S., postmasters gazed enviously at the paper messages rocketing across Europe. By the 1890s, the Postal Service began building municipal tube systems of its own—in Philadelphia, St. Louis, Boston, Chicago and New York. Letter carriers were still needed to go door-to-door, laboriously picking up mail and bringing it to a post office—but at that point tubes took over, shooting the mail across town to other post offices with pneumatic speed. One tube even crossed the Brooklyn Bridge, directly connecting the borough’s post offices to those in Manhattan.

Traffic was conquered. “A wagon might take 12 minutes to go between post offices, but a pneumatic tube might take two,” says Nancy A. Pope, curator at the Smithsonian National Postal Museum. American tubes were so big—up to eight inches in diameter—that a single canister could hold 600 pieces of mail. (New York’s first test canister contained a Bible, a flag and a copy of the Constitution.)

At its peak, the New York City tubes were carrying an astonishing six million letters a day, according to the Postal Service. Postal workers shot canisters off roughly every 15 seconds, with each one racing along at 30 miles an hour. The exchange of mail in New York sped up so quickly it began to resemble today’s email or tweets, with recipients trading notes all day long.

“If I’m a wife at home, I’d get a letter from my husband saying, ‘The boss is coming to dinner!’” Pope notes. “I’d write back saying, ‘OK, what am I serving?’ He’d write back saying, ‘Pork roast.’ And this all happens well before 1 p.m.”

The systems were physically gorgeous. The gracefully arcing pipes were fitted with brass connections, the canisters launching with loud shushing sounds—then popping out at the destination, slightly slick with the oil that lubricated the inside of the tubes. “It was steampunk long before they had steampunk,” says Mike Olivier, an amateur historian and engineer in Toronto who has published several papers on pneumatic tubes.

The tubes had their problems, particularly given how complicated they were. Canisters would get stuck, and workers performed arcane rituals to determine where the jam was located. In Paris, they fired guns down the tube and listened for the moment of impact. In the winter the system could clog with ice; in Berlin they poured wine into the tubes to defrost them.

Nonetheless, the lightning speed of the tubes was intoxicating. Pundits declared it was the wave of the future. “The present era is likely to be known to history as the pneumatic age,” exulted the Washington Post in 1893. Forced-air systems were like “little tornadoes caught and trained to serve you,” as the founder of the Daniels & Fisher department store said. The magazine Compressed Air devoted pages to the new industry.

“It represented efficiency, the marvel of instantaneous communication,” says Shannon Mattern, a faculty member in media studies at the New School.

**********

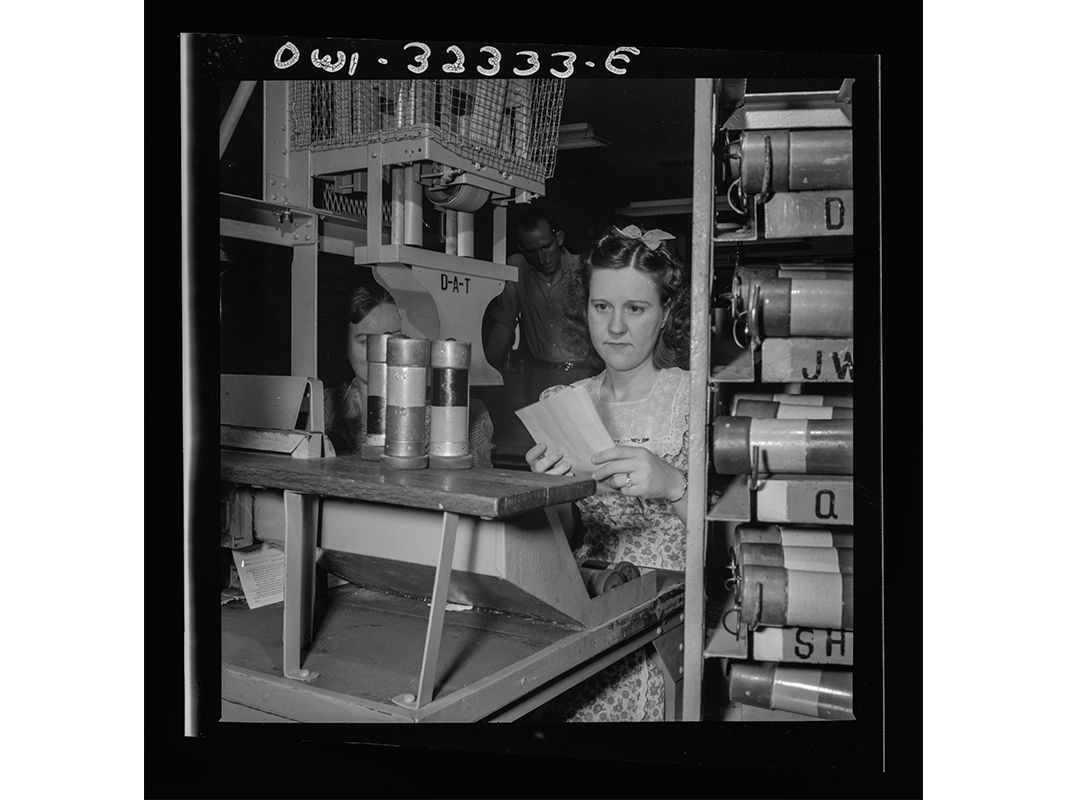

In a precursor to the hyperloop, people didn’t just move messages through tubes. They moved objects, particularly in companies and stores that built internal tube systems. Department stores blasted cash and small products like jewelry through for delivery. They located their cashiers in a central office to keep the money supply in a safe location—with shop-floor sales agents shooting customers’ payments there, then receiving change in “less than a minute,” as Scientific American marveled in 1903. (“Pneumatic Tubes Supersede Cash Boys,” cheered the Monthly Journal of the Brotherhood of Locomotive Engineers.) Tubes even transmitted power. Paris, which developed the world’s largest pneumatic-messaging network, also created a system for powering public clocks by compressed air. Indeed, the engineers building the Niagara Falls power project initially considered using the mammoth falls to generate compressed air that would be sent via pneumatic tube to Buffalo to power devices there.

Visionaries predicted that ever huger tube networks would emerge, allowing shops to deliver goods right to the home. A magazine writer even giddily called for tubes to deliver food in Berlin. (“With the elimination of all stoves and ovens in the home, the fame of German women for tasty cooking may soon pass into obscurity,” he wrote.)

The ultimate dream? Moving people. Science fiction authors of the day wrote wild tales of humans riding in air-blown vehicles. In the short story “In the Year 2889,” Jules Verne described people riding in pneumatic tubes “which convey them with a speed of a thousand miles an hour.” In New York, before the construction of the city’s subway, the entrepreneur Alfred Beach wanted to build an entirely air-propelled system, going so far as to actually construct a one-block underground test track beneath Broadway. But he couldn’t get investors interested because the physics seemed too unsettling.

“Everyone was worried that the start and stop would be so violent, everybody would get whiplash,” Pope says.

**********

Indeed, the very physicality of pneumatic tube systems is what, in the end, led to their demise.

After World War I, as U.S. cities grew rapidly, post offices needed to relocate. But that required tearing up and moving the tube systems—a brutally expensive endeavor. What’s more, a rival technology had emerged: the truck. Trucks could move large masses of mail around quite cheaply and quickly, and they also finally allowed for “parcel post,” the easy shipping of big packages. Tubes couldn’t compete with that. By the 1950s, many urban systems in the U.S. had been shut down, and the New York system was finally shuttered in 1953.

Europe held on a bit longer. The Parisian tube system operated until 1984, right up into the computer age. Prague had a tube network functioning until 2002, when flooding so damaged the hardware that the system was permanently shuttered.

Even as the digital age dawned, pneumatic tubes still felt somehow like a superior technology, a glimpse of a future that should have been. “If the equipment is old, the idea is terribly modern,” Jacques Lepage, director of a pneumatic-transport firm in Paris, said in 1984. “You can move things around extraordinarily quickly through the system here.”

**********

In the next few years, we should know if the hyperloop can reboot the dreams of pneumatic transport. Dirk Ahlborn and his team aim to begin work on a trial system—a five-mile line—in Quay Valley, California. By 2018, he thinks he’ll be able to convey human passengers. Meanwhile, the rival team at Hyperloop Technologies is designing its own prototype at a converted factory in Los Angeles.

But will anyone want to ride in such a device? Wouldn’t it seem claustrophobic, like being jammed inside a metal tube?

Sure, says Ahlborn. But that’s already what a lot of modern transport feels like. “It’s probably very much like what you already know from driving in a car, from being in a plane. I just came back from Dubai and the airplane was traveling over 500 miles an hour.” The harder questions, really, are the zillions of engineering challenges—like “acceleration and deceleration.” The hyperloop can’t launch off too quickly or people will be uncomfortable or even black out. Even more challenging are the politics, such as acquiring the right of way to build the tubes. California is sufficiently congested that even Ahlborn thinks that, practically, an L.A.-to-San Francisco ride would come much later than in other parts of the country, or even other countries.

The hyperloop is a long shot, pun intended. But if pneumatic transport happens, it would reshape cities and countries around the world. Ahlborn predicts it would be much cheaper than air or traditional rail—in fact, a ride between two cities a few hundred miles apart could cost just $30 one way. And if you could ship just-in-time products across state lines in mere hours, manufacturing could bloom in inexpensive, underdeveloped areas. Entirely new bedroom towns could emerge, far from major urban centers.

“What if someone built a community that’s 40 miles away, that’s cheap and nice, and you built a hyperloop to connect to it?” he asks. “In Quay Valley, a house could cost you $250,000, with top-of-the-line tech, a walkable green city, and within minutes you’re in L.A. or San Francisco. What kind of influence would it have on a city like Detroit?”

It sounds like Jules Verne. Yet there’s a whiff of practicality, too. After all, the dream of pneumatics has never entirely died. The big, citywide postal systems are gone, but many companies still use internal tube systems to move physical things around quickly. Hospitals are holdouts: Stanford University Hospital has four miles of tubes through which staff shoot lab samples and medication back and forth, traveling up to a quarter of a mile in under three minutes. And the flagship Swatch store in Manhattan uses tubes to blast watches up from inventory.

In an age where the Internet has accelerated our bits and bytes, there’s still some value, it seems, in accelerating our atoms.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Clive_Thompson_photo_credit_is_Tom_Igoe.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Clive_Thompson_photo_credit_is_Tom_Igoe.jpg)