This Folded Paper Fans Out Into a Full-Size Bike Helmet

The EcoHelmet, this year’s James Dyson Award winner, could be used by bike shares across the world

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/26/a8/26a8f8a2-5481-4cc7-a63c-9d7dce30df02/ecohelmet-closeup-bike.jpg)

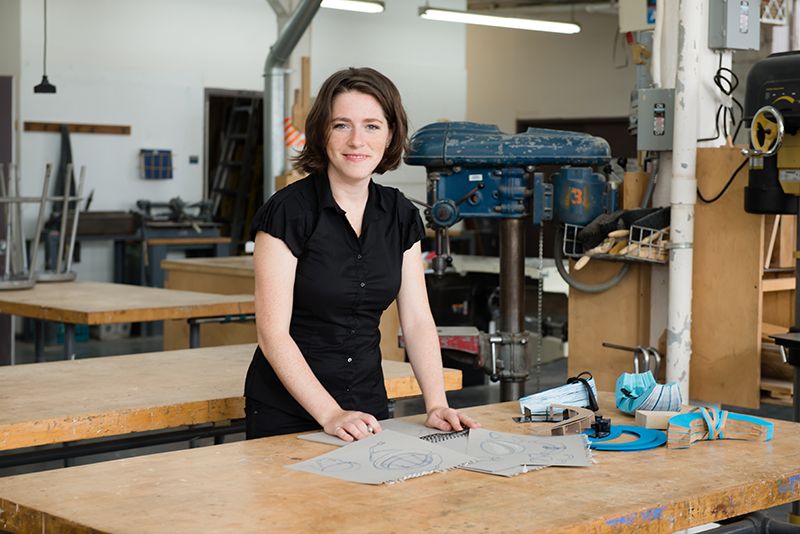

Isis Shiffer’s life revolves around bikes.

While working at Bilenky Cycle Works in Philadelphia, she designed custom bikes. Each one had its own artful flair—a tiny metal manta ray delicately perched atop the top tube, or art deco flourishes along each joint.

Now based in New York City, the designer rides her “uglified” '70s Viner dubbed “Stanley” almost everywhere she goes. If she’s not on her trusty steed, she rents a bike.

These days, such a fervor for cycling is easier to satiate than ever, with bike share programs popping up around the globe—from Malaysia to Alaska. But Shiffer noticed one thing conspicuously missing from most of these stations: Helmets. With more than 800 cyclist deaths in the U.S. in 2015, concern is rising for the hoards of bare heads bobbing to their beats while pedaling the city streets.

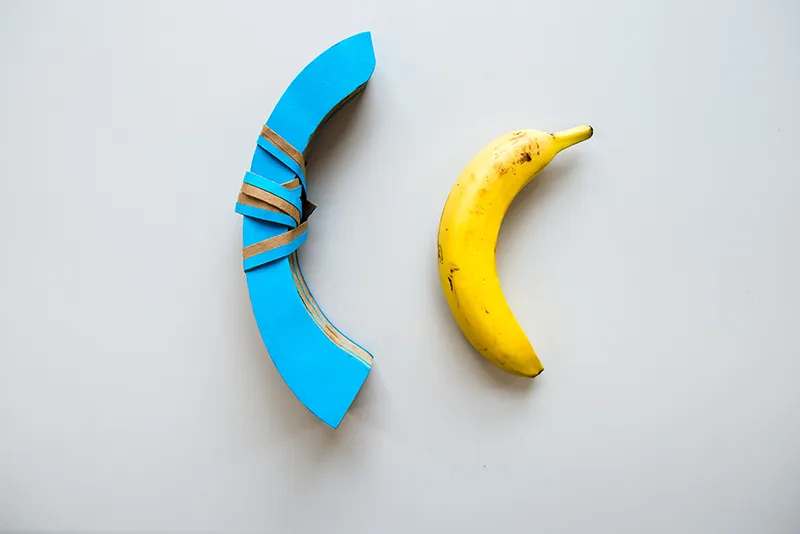

To fill this gap, Shiffer created EcoHelmet—a foldable, recyclable helmet constructed of paper with a water-resistant coating. When flattened, the helmet is roughly the same size and shape as a banana, but it fans out into a full-size helmet. The whole thing is reminiscent of the honeycomb tissue paper balls strung from the ceiling at parties. But unlike those flimsy decorations, this gear can take a punch.

This week her roll towards production just got a push. EcoHelmet is this year’s 2016 James Dyson Award winner, which comes with $45,000 for continued product development.

The international competition, now in its 14th year, “celebrates, encourages and inspires the next generation of design engineers,” according to the website. The winning designs are all clever but technically feasible products that offer real-world solutions to significant problems. Runners-up in the competition include Respia, an asthma management system that helps the user monitor medication usage and tracks lung health with a wearable patch, and Smart Contact Lens Platform, a contact lens that can monitor the wearer’s blood glucose for improved diabetes treatment.

"EcoHelmet solves an obvious problem in an incredibly elegant way. But its simplicity belies an impressive amount of research and development,” James Dyson says in the company’s press release about the award. “I look forward to seeing EcoHelmets used in bike shares across the world."

The helmet owes its strength to its proprietary honeycomb design, Shiffer explains. Regular honeycomb paper is known for its impact-absorbing powers and is regularly used in boxes and padding in the shipping industry. But these patterns all have parallel cells. “You can hold it up and see all the way through,” she says. EcoHelmet, however, uses a radial pattern, so each cell gets larger the further away from the head it is.

“It can absorb a blow from the front, the back, the side. Every blow is perpendicular to the head all around the helmet,” she says. “It works almost better than polystyrene in the way it spreads impact around.”

Shiffer had long hoped to create a travel-friendly helmet, but began working on the design while studying at Keio University in Tokyo in 2014. Her goal wasn’t just to make a rugged, foldable helmet. She wanted it to be cheap enough to sell at bike rental stations and and also to not contribute to growing landfills. Shiffer had a hunch that the honeycomb could meet her many requirements.

One of the most challenging aspects of the design was figuring out a suitable look. “It took a while to come up with a shape that doesn't look ridiculous,” she says. Her first design looked something like a pineapple. “I thought it was clever,” she adds. But everyone else claimed no one would ever wear it.

So Shiffer headed back to the drawing board to work on a pattern that more closely resembled traditional cycling helmets, but still incorporated the durable honeycomb. The EcoHelmet rose from these experiments.

Shiffer has extensively tested her prototypes with increasing sophistication over the years. Her first tests involved jumping up and down on her paper waffles or hitting them with hammers. When she relocated to the Royal College of London, she gained access to their crash labs, where she could more methodically gauge their strength, dropping heavy weights on her prototypes. Though her tests proved successful, in order to earn certification from the Consumer Product and Safety Commission she is now seeking out third party safety verification.

Shiffer’s design isn’t the only foldable helmet out there. These helmets greatly vary—from Morpher’s turtle shell-like design that collapses in half or Closca’s tiered design that flattens from the top—but these alternatives are all largely made of expensive traditional helmet materials such as fiberglass, polystyrene and plastic. The combination of inexpensive, environmentally friendly materials and simple design certainly gives EcoHelmet an edge.

A handful of cities already have compulsory bike helmet laws securely in place. And Shiffer’s new design could further help protect cyclists around the world, selling for around five dollars at city bike stations—depending on final decisions on materials, she says. (Shiffer explains that the helmets could alternatively be made of a recyclable plastic.)

One of the greatest concerns with EcoHelmet is how long the product would last. “Paper is fine under impact, it's fine under flexion [but] it does not like abrasion,” she says. “So I think what's going to kill [the helmets] is rattling around on the bottom of somebody's messenger bag for a week.”

Shiffer is currently considering how to create a visual indicator, like those on some toothbrushes, that disappears or changes color when the helmet is ready for the recycling bin.

Her next steps, she says, are to continue work with a partner company in Los Angeles to find manufacturers that can help finalize the details of the helmet and identify environmentally responsible and ethically sourced materials to use, all the while keeping costs low.

The Dyson award will not only bring further attention to Shiffer’s innovative work, but will help her get EcoHelmet to market even faster.

“I think the most exciting thing for me is to see what a huge international response it's gotten,” she says. “I was absolutely not expecting [it].”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Wei-Haas_Maya_Headshot-v2.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Wei-Haas_Maya_Headshot-v2.png)