Could This New Armband Prevent Thousands of Workplace Injuries and Fatalities Each Year?

Proxxi CEO Campbell Macdonald describes his cloud-connected wearable that detects high-voltage areas

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/a8/28/a8288180-4fc3-4979-b3b8-dcf8f0423b22/proxxi-main.jpg)

Every year in North America, 2,000 people—utility and construction workers, first responders, and even security guards and groundskeepers—are electrocuted on the job. The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) lists electrocutions among construction’s so-called “Fatal Four.” (Other fatalities are the result of falls, being struck by an object, or getting caught in tight spaces or between objects.)

On-the-job electrocutions can happen for a variety of reasons, from coming in contact with an active power source that should have been disabled to accidentally hitting a power line hidden in a tree. While they are widespread, electrocutions are chronically underreported. Even when they are reported, they can be buried in paperwork and bureaucracy, says Campbell Macdonald.

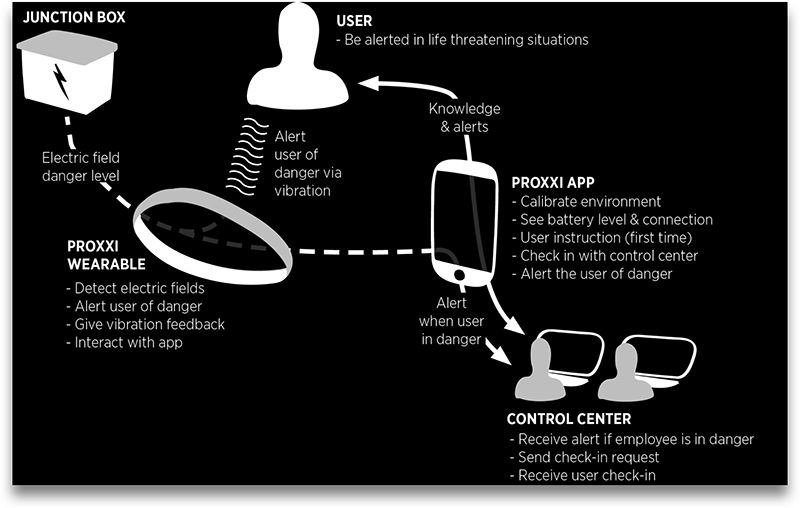

Macdonald is leading a charge to change that and to improve workplace safety when it comes to dealing with electricity and power sources. The serial entrepreneur (his last company, a marketing performance analytics platform called Pathful, was acquired by mobile shopping platform Mobify) is the CEO of Proxxi, a Vancouver, British Columbia-based company that makes a cloud-connected, wearable armband built to sense nearby electrical charges. Approach energized equipment, and the band automatically vibrates to alert the wearer about the invisible, deadly danger. It’s the only product of its kind on the market—most electrical charge sensors are handheld and workers may forget or not have access to them—and will be on the wrists of its first customers later this summer.

Macdonald shares his story with Smithsonian.com.

What was the impetus for building the Proxxi band?

BC Hydro, the major utility in British Columbia, Canada, initially identified a technological need for a wearable to sense electricity. The idea was a bit broad, but it was clear they wanted something for utility workers to wear around equipment that should be de-energized but is still live.

My business partner Richard Sim is an engineer; we met at the Vancouver Hack Space and have known mutual friends and colleagues for years. BC Hydro gave us a small grant, and within a few months in the spring and summer of 2015, we’d developed a working prototype. We spun off a company around this because we had a product that worked and a clearly identified enterprise use case that can impact the lives of millions of workers every day.

For the past year, we’ve been working to build a business around this and determine which customers to approach first. We’re starting with the electrical utility industry, which has the highest instance of electrical-related injuries and also sets the standard for electrical industry workplaces, such as industrial manufacturers, construction sites and first responder teams.

What’s your elevator pitch?

We have several value propositions. One is the value proposition for the worker. Our hardware band keeps workers safe. They can follow industry procedures, such as using handheld electrical contact sensors to detect an electrical charge or talking to colleagues about a work site, and each step is still prone to human failure. Our band is always on, an always aware second set of eyes to sense something that is super dangerous and invisible. It’s simple for anyone to understand and use.

There are other interesting cases. Proxxi is a smart, connected device, so not only does a worker sense danger but so does the organization or parent company, which receives reports from the field. They can find out from the armband that they have a man down and can check in on that person.

They can also see the data aggregated in analytics and reports and figure out: are individuals behaving differently than others? Are there gold standard employees? Do certain teams behave differently? Could there be a management issue? Are crews stationed in or approaching unsafe working environments?

Currently, some companies make decisions based on incomplete or bad data. By observing worker behavior, we can offer surface insights and also much richer data reports, which can in turn reduce risk, mitigate cost and save lives.

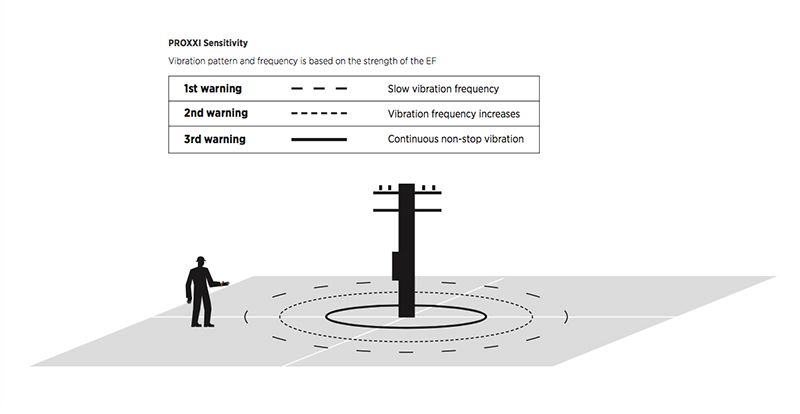

Our sensor can sense distance and source voltage, which is new and novel. Our first application is the Proxxi band. But there’s a case for creating other items to monitor every electrical device around us.

How did you build the Proxxi armband?

We built a printed circuit board (PCB) that uses commodity hardware to sense the electrical field. So really, we put this together without any true custom components. On top of that, we wrote firmware [permanent software] to interpret the strength of the electrical field, the source voltage and the distance from that source.

The R&D process sounds pretty straightforward. Did you encounter any challenges that you didn’t anticipate?

I think many large companies come to problems with a certain lens, often because they have a way of currently solving a problem through incremental improvements. We don’t have a background in the electrical utilities space and came to this with beginner eyes. We don’t know how these things are typically done—and we surprised ourselves with the result.

People come up with novel solutions all the time. Here is a classic case of product development and getting that product to market. Building a better mousetrap is great, but we have to convince buyers our mousetrap is better in terms of safety, more economical and a better enterprise value.

What’s next?

We’re raising our seed round right now and have several institutional investors interested.

Beyond the funding side, we’re still running field trials of the Proxxi band. The technology has been validated, so the product just needs to work in the field and be acceptable to buyers. The early field test data is promising, and though we still need to make a few product improvements, we’re on track to release commercial products this summer. The price will start at $300 per band per year [and includes the connectivity and data available to the organization], and we’re projecting $1.2 million in revenue in our first year on the market.

Because we’re a small team, we work very quickly. We have a single product, and when we wake up every morning, this is what we’re working on. Buyers are keenly anxious to get this in their hands, so right now, all we can do is build.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/brittany_headshot_crop.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/brittany_headshot_crop.jpg)