One Japanese Company Makes Half Of The World’s Zippers

How YKK came to dominate pants around the world.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c4/a7/c4a7799d-f2dd-43d5-8710-2e0ab025161d/ykk.jpg)

Take a look at a zipper on any given pair of pants and chances are it’s inscribed with the letters “YKK,” an acronym stamped on some 7 billion zippers a year. Every one of them is manufactured by a single Japanese company behind what might be one of the most ubiquitous brands in history.

Those three capital letters stand for Yoshida Kōgyō Kabushikigaisha, which roughly translates to Yoshida Manufacturing Shareholding Company. Founded by Tadao Yoshida in 1934 as the zipper business was beginning to boom. Inspired by Andrew Carnegie’s capitalist manifesto, The Gospel of Wealth, over a few decades Yoshida transformed his small company into a massive, worldwide concern, George Pendle writes for Atlas Obscura.

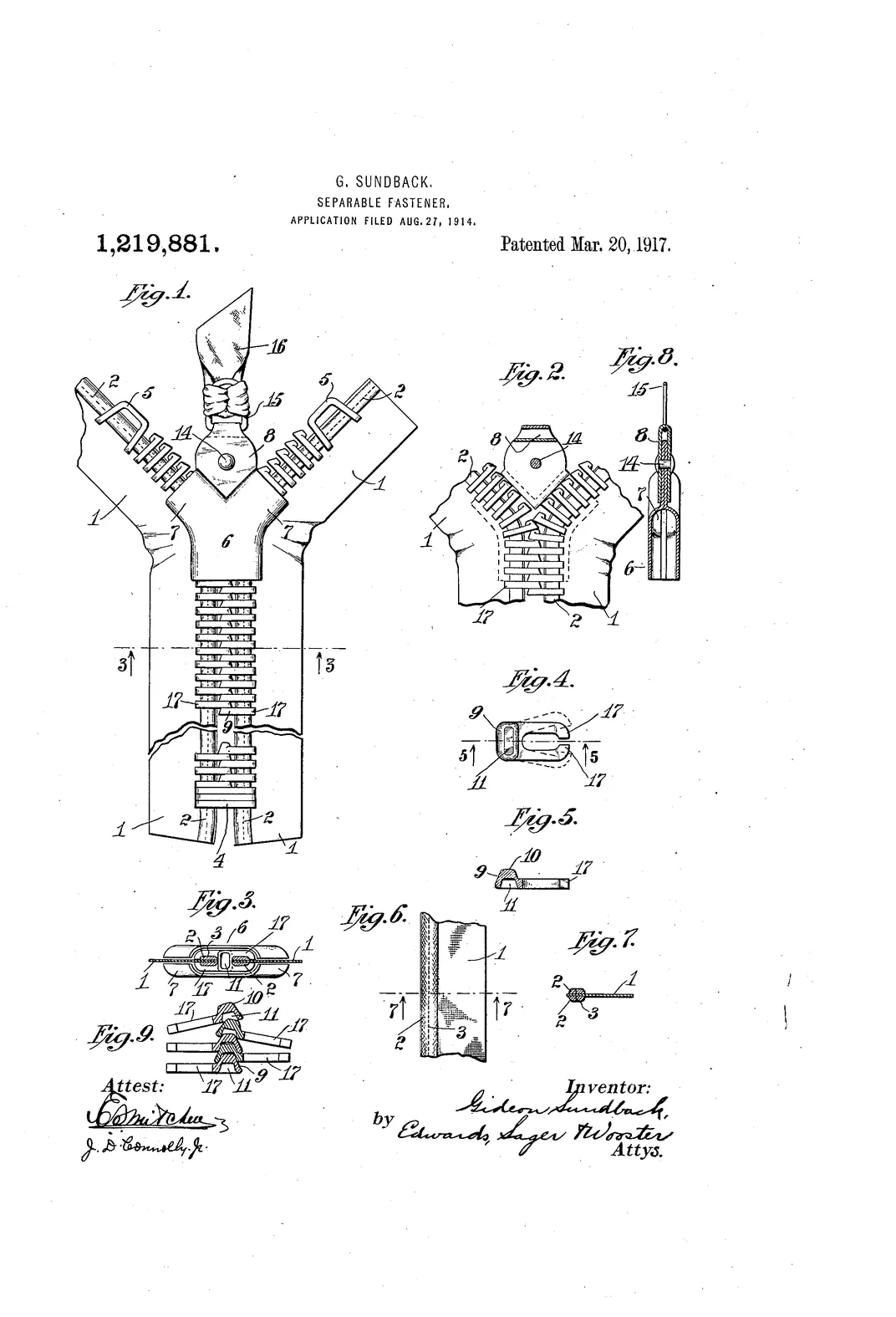

As commonplace as zippers are today, the humble fastener has only existed for just over a century and wasn’t widely used until the 1930’s. People had been trying to come up with a modern alternative to buttons since the mid-19th century, but it wasn’t until a Swedish inventor named Gideon Sundback designed an “automatic fastener” that the device became popular, Pendle writes. The name itself came from the owner of a boot company that used an early zipper on a new shoe called the “Mystik,” which was selling terribly.

“What we need is an action word,” the executive said, according to Pendle. “Something that will dramatize the way the thing zips…Why not call it a Zipper?”

After that, sales skyrocketed. By the end of World War II, Talon, the company for whom Sundback worked, was selling 500 million zippers a year. But by the 1970's, YKK toppled the zipper’s inventor through an obsessive dedication to manufacturing the perfect zipper, Seth Stevenson writes for Slate.

In his quest to beat his rival zipper-makers, Yoshida brought almost every aspect of the design and manufacturing of his product under YKK’s umbrella. As John Balzar wrote for The L.A. Times in 1998:

YKK smelts its own brass, concocts its own polyester, spins and twists its own thread, weaves and color-dyes cloth for its zipper tapes, forges and molds its scooped zipper teeth, extrudes the monofilament for coil zippers, hammers and paints the sliders, clamps the stops, attaches the dangley pulls in a thousand varieties, and even fabricates the cardboard boxes in which zippers are packaged.

Yoshida codified his ideals in what became YKK’s “Cycle of Goodness,” a management philosophy stating that “no one prospers unless he renders benefit to others.” And this philosophy seems to work, at least as far as zipper quality goes. “There have been quality problems in the past when we’ve used cheaper zippers,” sportswear designer Trina Turk tells Stevenson. “Now we just stick with YKK. When the customer is buying $200 pants, they better have a good zipper. Because the customer will blame the maker of the whole garment even if the zipper was the part that failed.”

The zipper may just be a tiny piece of metal, but those three capital letters mean a lot.