Fuel from Seawater? What’s the Catch?

Scientists at the U.S. Naval Research Laboratory recently flew a model plane using a liquid hydrocarbon fuel they sourced from the ocean

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/d2/0d/d20d6712-8fac-435e-99ca-f4e4b9a66fc7/seawater-fuel.jpg)

For several years now, the U.S. Navy has been looking for a way to fuel fighter jets aboard aircraft carriers out in the open ocean without having to rely on refueling ships. And what could be more efficient than using the water that’s available in every direction as far as the eye can see?

Now, scientists at the U.S. Naval Research Laboratory have demonstrated the ability to recover carbon dioxide and hydrogen from seawater and turn it into a liquid hydrocarbon fuel—the kind of stuff that can power a jet engine. In fact, researchers recently flew a model plane as proof of concept.

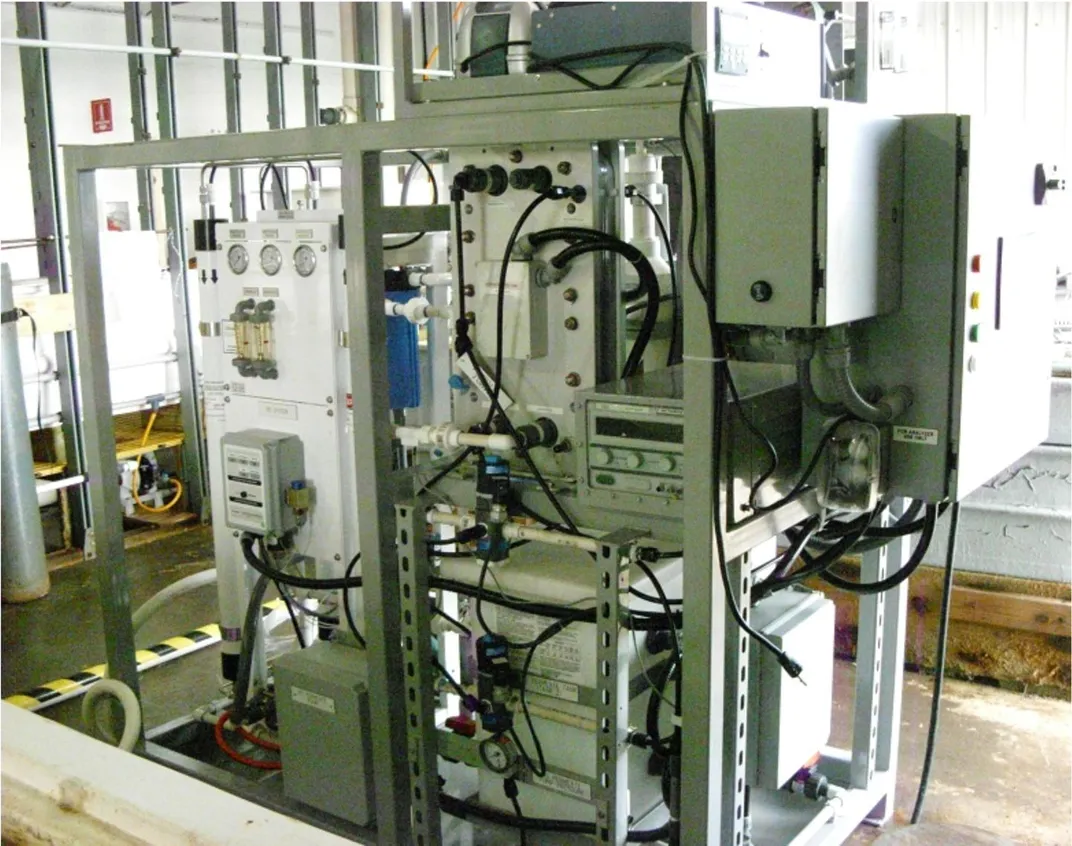

Using a proprietary electrochemical device, researchers were able to pull carbon dioxide from the water, get hydrogen as a byproduct, and then bounce the two gases off each other to manufacture the liquid fuel. The scientists say they can pull about 97 percent of the dissolved carbon dioxide from the water and convert about 60 percent of the extracted gases into hydrocarbons that can be made into fuel at the cost of approximately $3 to $6 per gallon. The low end is equivalent to today’s jet fuel costs, while the high end would be double the price. The fuel could be commercially viable in 10 years.

So what’s the catch? Well, there are many.

First, carbon dioxide concentration in seawater is about 100 milligrams per liter. That’s 140 times greater than that of air, but still not very much in real terms. One report calculates that you’d have to process close to nine million cubic meters of water to make 100,000 gallons of fuel, and that’s assuming 100 percent efficiency. Assume far less efficiency, and you have to assume much more water. And the more water you process, the more plankton and other little critters you remove from the food chain—with potentially catastrophic results for marine life.

Secondly, you’d have to pump all that water into the conversion machine using some form of energy, and if the ship uses fuel to make the electricity to do the conversion job, then the whole process would be pointless. So the conversion would need to take place on a nuclear-powered aircraft carrier, where energy is relatively clean and cheap.

Then, if 60 percent of the gas is converted, what happens to the other 40 percent, including the 25 percent that becomes environmentally unfriendly methane?

And doesn’t flying jets simply put the carbon back into the atmosphere? Yes, says the Navy, noting that at least in theory, the system would be in constant equilibrium as carbon went from the sea to the air and then back into the sea to be extracted again.

Like every other alternative energy source, seawater fuel will only succeed if everyone agrees that what comes out of the process is worth significantly more than what goes into it. In this case, with national defense as a significant part of the motivation, chances are the research will continue.

This article was originally published by the editorial team at XPRIZE, which designs and operates incentivized competitions to bring about radical breakthroughs for the benefit of humanity.