Ultra Antifreeze Prevents Ice From Even Forming

A new nano-technology can be applied to metals and causes ice and frost to slide off before they have a chance to stick

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/20120612023037Ice_2_Ice.jpg)

When water freezes on metal surfaces, it’s a problem. The aviation industry spends millions of dollars and countless hours spraying deicing fluid on the wings of planes as they sit waiting on wintery runways, while we personally learn about the trouble caused by ice from the time we spend chipping it from our freezers.

A team of researchers from Harvard has taken a different approach to removing ice and frost from metal: They’ve developed a special coating that prevents water droplets from sticking and turning into ice in the first place.

Deicing planes may be a thing of the past, thanks to a new coating called SLIPS. Photo by wikimedia commons user Mulag

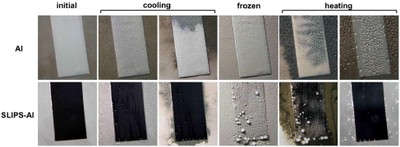

As detailed in a paper published Monday in ACS Nano, the group, led by professor Joanna Aizenberg, has created a way to produce metal coated with what they call “slippery, liquid-infused porous surfaces.” The coating—denoted by the acronym SLIPS—repels water droplets and ice simply by the power of gravity. The group tested aluminum refrigeration fins coated with SLIPS at -10 degrees Celsius and 60 percent humidity, and the technology significantly outperformed typical “frost-free” cooling systems in terms of preventing frost from forming over time.

Conventional aluminum refrigeration fins (top row) were clearly outperformed by those coated with SLIPS (bottom row) in the study. Photo courtesy Harvard University

How does SLIPS work? Frost can only stick to a piece of metal due to microscopic imperfections and defects that exist on a molecular level, giving water droplets something to stick to as they freeze. Scientists and engineers have long tried to figure out how to create absolutely smooth metals that would prevent this from happening, but large-scale manufacturing processes make this effectively impossible.

Aizenberg’s team responded by creating a two-stage process—which can be applied to metals already manufactured—that presents an entirely smooth surface to the elements, causing ice and water droplets to slide off before they have a chance to adhere. First, the metal is coated with a rough, porous solid material. Then a liquid lubricant is applied that sticks to the pores in the solid nanomaterial, creating an outer surface that is perfectly flat on the molecular level, so that gravity alone can prevent ice from forming.

As a result, SLIPS can be applied to metals of any shape and size, even on a large scale, and it solves all sorts of problems associated with icing and frost. On any vertical surfaces, ice sheets will fail to form in the first place, and even on horizontal planes, any ice that does form will go flying with a slight nudge, since there are no imperfections to which it can bind. Airplane wings, railings, stairways, refrigeration equipment, roofs, signs and other objects could easily be kept free of ice and frost using the coating.

The team also projects substantial energy savings as a result of the new technology. Current ice removal methods require the transportation of special chemicals and equipment, whereas SLIPS-treated materials will shed ice readily with minor agitation, or perhaps even a gust of wind. The substance is also non-toxic, anti-corrosive, and it works in environments with extreme cold and high humidity.

Like the coating we covered that allows ketchup and to slide easily out of the bottle, this is a cutting-edge technology that we could easily see enter our daily lives. Instead of salting metal staircases or waiting as ground crews deice passenger planes, we could just manufacture structures and vehicles that resist ice to begin with. As summer hits, ice might not be the biggest concern on your mind, but when winter hits, you’ll be glad this crew of scientists has been hard at work.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/joseph-stromberg-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/joseph-stromberg-240.jpg)