Electronics That Can Melt in Your Body Could Change the World of Medicine

John Rogers, a revolutionary materials scientist, is pushing the boundaries of the medical world

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Rogers-ingenuity-tri-grass-631.jpg)

Conventional wisdom has it that electronics and water don’t mix: You know this even if your cellphone has never slipped from your hand into, say, the bathtub. So it was with some alarm this past summer that I watched John A. Rogers cheerfully shoot water at an integrated circuit.

We were in a lab at the University of Illinois at Urbana-Champaign, and Rogers—a materials scientist there, and the picture of wholesomeness in crisp polo, khakis and Boy Scout ring—had availed himself of a generic spray bottle. The circuit, a radio oscillator, glistened atop a patch of artificial grass that some postdocs had set up as an outdoorsy backdrop.

The first spritz of water caused the circuit to slowly curl, like a scrap of paper that had just caught fire. When Rogers sprayed again, the circuit hunkered and collapsed onto itself. The next sprinkles were deathblows: The circuit and its transparent silk backing shriveled into a liquid ball, which dribbled down a long blade of grass. What seconds earlier had been a functional piece of electronics with diodes, inductors and silicon transistors was now no more conspicuous—or long for this world—than a drop of morning dew.

“Yeah, it’s pretty funky,” says Rogers, who is 46 and has the earnest manner of the guy-next-door. But this was no parlor trick. Rogers and his team of researchers designed the circuit for “transience”: It was born to die. And as Rogers sees it, that could launch electronics into uncharted waters in medicine, environmental studies and national security. We may soon see sensors that track blood pressure in the aorta after heart surgery, then dissolve once a patient is out of the woods. Or a nontoxic cellphone we flush down the drain on purpose when we’re ready for an upgrade. Or sensitive battlefield technology that goes plop-plop-fizz-fizz before it falls into enemy hands. “Our hope is there’s a lot of value in this,” he says. “It’s not just a curiosity.”

Transient electronics may be the most mind-bending invention yet to come out of Rogers’ lab, an idea factory whose rate of publication in major scientific journals is matched only by its output of headline-grabbing gizmos. Rogers, who holds one of the university’s loftiest chairs, has appointments in five departments. He also directs the school’s Frederick Seitz Materials Research Laboratory. He authors or co-authors dozens of articles most years, many for marquee journals like Science and Nature. But his lab, for all its serious science, could just as easily be a back lot for the Bionic Man.

Rogers and his collaborators have built cellophane-like sheaths of electronics that wrap the undulating surfaces of the heart. They have made eyeball-shaped cameras that mimic human and insect sight, and soft threads of tiny LEDs that can be injected right into the brain. During my visit, a postdoc showed me a transistor-infused temporary skin tattoo—“epidermal electronics”—that could free hospital patients from the tangle of wires and clip-on sensors that keep doctors abreast of vital signs.

Rogers rose to stardom in the scientific world not just for dreaming up these ideas, but also for puzzling out how to build them. Many of his insights are the product of a studied disregard for status quo notions about silicon-based circuits.

Rigidity, stiffness and durability are the cornerstones of modern electronics. They are embedded into its very vocabulary: microchip, solid state, circuit board. For 90 percent of the things electronics do today, that may be fine. Rogers is interested in the other 10 percent: He wants to make hardware soft—soft enough for the moving, swelling and pulsing contours of the human body and natural world. His target is nothing less than the border between man and machine. The brain “is like Jell-O, and it’s time-dynamic, and moving around,” Rogers says. “A silicon chip is completely mismatched in geometry and mechanics, and it can’t accommodate motion without constraining that motion.”

Sure, an electronic probe can be sunk into brain tissue. “But now you have a needle in a bowl of Jell-O that’s sloshing around.” Who’d want that?

For a short time, Rogers, like other researchers, saw plastic circuits as the solution. But plastic’s flexibility came at what turned out to be a great cost: Electrically it was 1,000 times slower than silicon, the superstar of semiconductors. “You couldn’t do anything requiring sophisticated, high-speed operation,” he says.

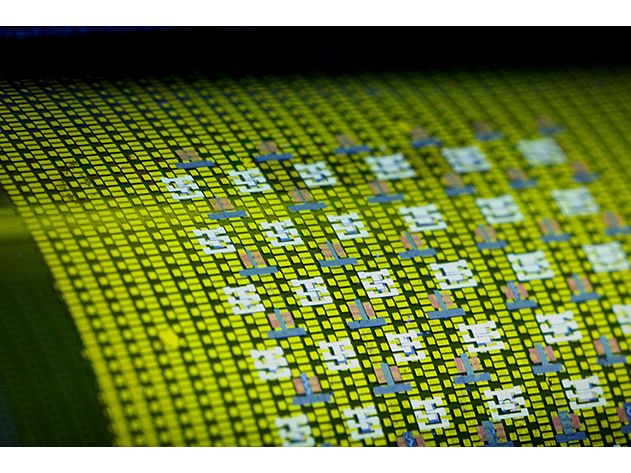

So he gave silicon a second look. He soon developed a technique for shearing it into sheets so vanishingly thin—100 nanometers, or one-thousandth as thin as a human hair—that it did something few dreamed possible: It flexed, twisted and, when threaded in a snaky pattern, even stretched. Then he went further. In a cover article in Science last year, he announced that if you made silicon skinnier still—35 nanometers—it would fully dissolve into biological fluids or water in a matter of days.

A conventional silicon wafer’s one-millimeter thickness, Rogers knew, had nothing to do with conductivity: The heft is there mainly so robots can move it through the various steps of fabrication without breaking.

“You have this gigantic industry based around wafer-based electronics, and for that reason, people traditionally look at silicon and say, ‘Well, it’s not flexible, we have to develop a different material for flexible circuits,’” he says. “But if you think about it more at the level of the mechanics, you quickly realize it’s not the silicon that’s the problem, it’s the wafer that’s the problem. And if you’re able to get rid of the underlying silicon materials not involved in the operation of the circuit, you’re left with a very thin sheet of silicon,” as floppy as loose-leaf paper.

At the end of one workday in July, Rogers slipped into a conference room beside his office and stepped out moments later in athletic shorts, white tube socks and sneakers. Before we left campus, to meet his wife and son for tennis at a public park, he gave me a tour of his office, whose bookcases were full of demos of his inventions, encased in plastic jewel boxes: The labels read “fly eye camera,” “proximity sensor on vinyl glove,” “stretchable solar cells,” “twisted LED.”

Rogers brushes aside the idea that his flexible and stretchable electronics represent any sort of quantum leap. “Our stuff is really just Newtonian mechanics,” he says. His silicon is to a factory-made wafer what a sheet of paper is to a two-by-four: the same salami, just sliced a lot slimmer.

“One of John’s strengths is he recognizes how to take a technology that already exists in a highly developed form and add something new to it so that it has new applications,” says George Whitesides, the renowned Harvard chemist, in whose lab Rogers worked as a postdoc. “He’s extraordinarily creative at this gap between science and engineering.”

Rogers’ transient circuits are sheathed in silk protein, which protects the electronics from liquid and can itself be formulated to dissolve in a few seconds or a few years. Inside the silk are circuit components whose materials—silicon, magnesium—break down into chemicals found in some vitamins and antacids. (In a speech to an engineering group last December, Rogers gulped down one of his circuits on a dare. “It tastes like chicken,” he joked with the audience.)

Years of clinical trials, followed by regulatory approvals, await any introduction of these devices into the human body, and precisely how to power and wirelessly connect with them is an area of active study. But the worlds of science, business and government have taken early and frequent notice. In 2009, the MacArthur Foundation, in awarding him a “genius” fellowship, called his work “the foundation for a revolution in manufacture of industrial, consumer and biocompatible electronics.” Two years later, he won the Lemelson-MIT Prize, a kind of Oscar for inventors. Each came with a check for $500,000.

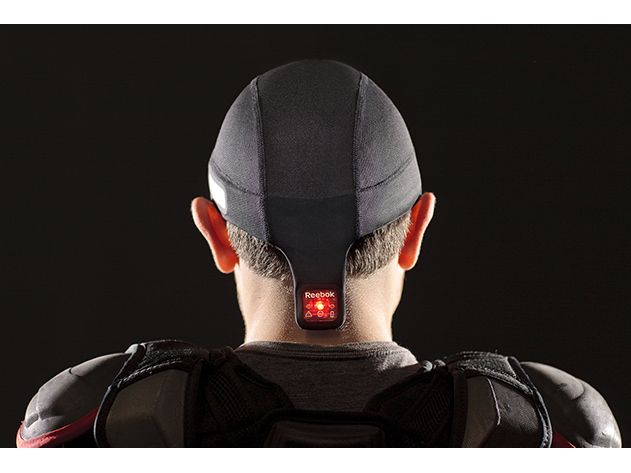

To harvest his vast patent portfolio, Rogers has co-founded four startup companies. They have raised tens of millions of dollars in capital and are eyeing markets—biomedicine, solar power, sports, environmental monitoring and lighting—as eclectic as his creative impulses. Earlier this year, one company, MC10, in partnership with Reebok, launched its first product: Checklight, a skullcap with flexible silicon circuits, wearable alone or under football or hockey helmets, that alerts players to potentially concussive head impacts with a set of flashing LEDs.

***

Rogers was born in 1967 in Rolla, Missouri, the eldest of two sons. Two years later, on the day his father, John R. Rogers, finished oral exams for a physics PhD at the state university, the family piled into a car for Houston. Texaco’s laboratory there had hired his father to scout for oil by acoustically searching subsurface rock formations.

His mother, Pattiann Rogers, a former teacher, stayed home while the boys were young, and wrote poetry, often about science and nature.

The family settled in the Houston suburb of Stafford, in a new subdivision that bordered pasture. John and his younger brother, Artie, would venture into the fields and return hours later with snakes, snapping turtles and a menagerie of “varmints,” his mother told me.

Pattiann stoked her sons’ fascination with nature, taking part in their outdoor escapades and often jotting down notes afterward. She would go on to publish more than a dozen books and win five Pushcart Prizes, as well as a Guggenheim fellowship.

When I asked if any of her poems were inspired by watching John as a boy, she directed me to “Concepts and Their Bodies (The Boy in the Field Alone),” about the intersection of natural mystery and scientific abstraction.

“Staring at the mud turtle’s eye / Long enough, he sees concentricity there,” it begins.

Rogers told me that childhood dinner conversations “would range from physics and hard science with my dad, and more inspirational aspects of science through my mom. It instilled the notion that creativity and the arts are kind of a natural part of science. Not just the execution of it, but the implications and insights that flow from it as well.”

Rogers, who attended public schools and would become an Eagle Scout, entered his first science fair in fourth grade with “this gargantuan parabolic reflector that could take the Texas sun and just absolutely make it nuclear in terms of the power you could generate.” In fifth grade, he won a districtwide fair with a box of mirrors and light sources that created the illusion of a man stepping into a UFO.

He finished coursework so quickly that much of his high-school senior year was independent study. With supercomputers at his father’s lab and reams of unsifted depth-sounding data, he wrote new algorithms for mapping the ocean floor and discovered a giant salt tongue at the bottom of the Gulf of Mexico. The results earned Rogers a raft of college scholarships at a Houston-wide science fair, held that year at the Astrodome.

In his undergraduate days at the University of Texas, Austin, he signed up to work in a chemistry professor’s lab. He labored shoulder to shoulder with senior researchers amid all that sparkling glassware, and was spellbound. Today he sets aside 30 to 50 spots for undergrads in his own labs, nearly as many as the rest of the materials science department combined. “I don’t need to look at grades: If they want in, they’re in,” he says. “It shows them that classroom instruction is important for science, but it is not science itself.”

He majored in chemistry and physics at Austin, and then earned master’s degrees in the same subjects at MIT. Keith Nelson, an optics expert at MIT, was so impressed by Rogers’ prodigious early record that he took the unusual step of penning a letter, urging him to pursue a PhD. “He just had so many indicators that he could achieve terrific things in science,” Nelson says.

In his second or third year of graduate school, Rogers found ways to streamline Nelson’s methods. In one notable instance, he replaced a cobweb of intersecting laser beams and painstakingly tilted mirrors—used to study the damping of sound waves—with a single light-diffracting mask that achieved the same results with one beam in a fraction of the time.

Had anyone thought of that before? I asked Nelson. “I can tell you we should have realized that way earlier but the fact is we didn’t. And I don’t mean just us,” he said. “I mean the whole field.”

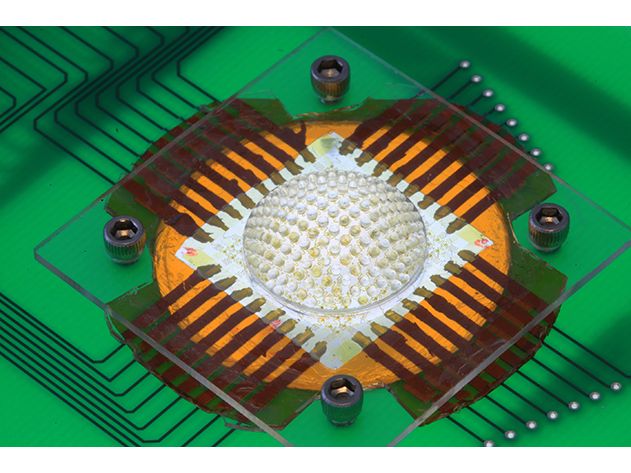

For his PhD, Rogers devised a technique for sizing up the properties of thin films by subjecting them to laser pulses. People in the semiconductor industry began paying attention even before he was out of graduate school. For quality control, factories need exacting measurements of a microchip’s ultrathin inside layers as they are deposited. The prevailing method—tapping the layers with a probe—was not just slow; it also risked breaking or dirtying the chip. Rogers’ laser approach offered a tantalizing solution.

In his final year at MIT, Rogers and a classmate recruited students from the school’s Sloan School of Management and wrote a 100-page business plan. Nelson reached out to a neighbor who was a venture capitalist, and before long the group had investors, a CEO and meetings in Silicon Valley.

The shift from classroom to boardroom was not always smooth. At a meeting at Tencor, a chip-testing company, Rogers projected transparency after transparency of equations and theory.

“Stop, this is too much,” a Tencor executive cut in. “Why don’t you tell me what you can measure and I’ll tell you whether we can use it.”

Rogers went through his list: stiffness, delamination, longitudinal sound velocity, thermal transfer, coefficient of expansion.

No, don’t care, no, no, the executive said. What about thickness? Can you do that?

Well, yes, Rogers said, though it was the one yardstick he hadn’t even cited in his business plan.

That’s what I want, the executive said.

“That was a seminal moment in all our lives,” recalls Matthew Banet, the MIT classmate who co-founded the startup and is now chief technology officer for a medical software and device company. “We went back with our tails between our legs.”

Back in Cambridge, they spent months tinkering with the laser system until it did exactly what Tencor wanted: measure variations in thickness as minuscule as one-tenth of an angstrom—or one one-hundredth of a billionth of a meter.

The give and take between industry and inventor was revelatory. Rogers saw that “sometimes the technology push drives scientific understanding, rather than the other way around.” He and his colleagues had already published papers on the laser technique, but Tencor’s requirements forced them back to the drawing board “to understand a lot more about the optics and physics and acoustics and signal processing.

“It put all the scientific research into the context of something that could have value beyond publication in a scientific journal.”

Rogers’ laser startup, Active Impulse Systems, raised $3 million in venture capital and sold its first unit, the InSite 300, in 1997. In August 1998, three years after its founding, the business was acquired in whole by Phillips Electronics, for $29 million.

***

If Keith Nelson’s lab taught Rogers how to measure, George Whitesides’ lab at Harvard taught him how to build. Rogers went there in 1995, right after earning his PhD. Whitesides’ passion at the time was soft lithography, a technique for using a rubber stamp to print molecule-thick patterns of ink. Rogers soon saw its potential for inking circuits on curved surfaces, like fiber-optic cable. That idea—and the patents and papers that followed—won him a job offer from Bell Labs, AT&T’s legendary research arm, in northern New Jersey. Rogers’ wife, Lisa Dhar, a fellow physical chemist and MIT classmate he’d married in 1996, was already working there; they had been conducting a long-distance relationship.

“For me, it was like paradise,” he says of Bell Labs, which had pioneered the transistor, the laser and landmark programming languages like C. “I was drawn to that interface between science and technology.” But the telecom crash of 2001 led to massive layoffs at Bell Labs, and then came another bombshell: A young researcher in Rogers’ department had fabricated data for a set of major papers, a scandal that produced national headlines. Rogers decided to move on—to the University of Illinois, he says, because of its storied engineering department and deep resources for interdisciplinary research. (Also, a baby—their only child, John S.—was on the way, and his wife’s family was from Chicago.)

Before long, Rogers had assembled a research group of 25 postdocs, 15 graduate students and several dozen undergraduates. The group’s size enabled collaborations so diverse they might be called promiscuous. Over my three-day visit, Rogers had meetings or conference calls with a Lehigh University nanotubes expert; a University of Arizona cardiologist; a thermal-imaging specialist at the National Institutes of Health; a team of theoretical physicists who’d carpooled down from Northwestern University; and a fashion professor who’d come from the Art Institute of Chicago to talk about LED-bespangled apparel.

During one of the half-hour slots into which he divides his 13-hour workday, we watched five undergraduates give precisely timed slide shows about their summer research projects. Rogers, his legs bouncing under the table as though racing toward some new revelation, pinged the students with questions, snapped a group photo and gave gift cards to the top presenters—all before the half-hour was up.

Whitesides told me that Rogers is unburdened by the “not invented here” syndrome that afflicts many scientists, who fear that collaborations somehow taint their originality. “John’s view is that if it’s a good idea, he’s perfectly happy to use it in a new way.”

“A lot of the most important advances in research are happening at the boundaries between traditional disciplines,” Rogers says. His Science article on transient electronics lists 21 co-authors, from six universities, three countries and one commercial consulting firm.

Students have inspired some of his best-known inventions. After hearing Rogers talk about soft lithography, one asked if the technology had ever stamped silicon, rather than just molecules of ink. “He didn’t have any idea how to do it, but he threw it out there as a question: the sort of question a first-year grad student would ask.”

The problem Rogers faced was, How do you turn hard silicon into a spongy ink pad? From a series of experiments, he found that if you sliced a silicon ingot into wafers at an unorthodox angle and then washed the wafer in a particular chemical solution, you could tenderize a thin surface layer that would come off on a stamp like ink. The pattern—a circuit element, for instance—could be lifted off and printed on another surface.

“No one had done that before,” says Christopher Bettinger, a materials scientist at Carnegie Mellon. Among the many technical enigmas Rogers untangled, he said, was “reversible stickiness.”

“If you lick your finger and put it in powdered sugar, you can pick up powdered sugar,” Bettinger said, by way of analogy. “But how do you then put the sugar down on something else?” Rogers did it with a shift in speed: To ink the stamp, touch and lift quickly; to inscribe onto a new surface, touch and lift slowly. The discovery allowed him to implant silicon “nanomembranes” just about anywhere: plastics and rubber, for his tattoo-like electronics, and silk, for the dissolvable ones. He found he could even stamp circuits directly onto skin.

Aleksandr Noy, a bioelectronics expert at Lawrence Livermore National Laboratory, told me that Rogers’ stature is a product of “papers, invited talks and record” but also of something intangible: “the cool factor.”

***

The money for Rogers’ transient electronics work comes mainly from the Defense Advanced Research Projects Agency (Darpa), a Department of Defense unit that funds some of the wildest ideas in science.

Rogers, who has a government security clearance, says that Darpa wants him to remain mum about specific military apps. “But you can imagine,” he says. I didn’t have to. A January 2013 news release on Darpa’s website is explicit about the aims of the “Vanishing Programmable Resources” program, which underwrote Rogers’ research: The agency is looking for ways to deal with the radios, phones, remote sensors and other sophisticated electronics that wind up “scattered across the battlefield” after U.S. military operations. If captured by the enemy, this e-waste could “compromise DoD’s strategic technological advantage.

“What if these electronics simply disappeared when no longer needed?” the release says.

No doubt Q—the British secret service’s lab chief in the 007 films—would be impressed. Rogers, for his part, seems plenty jazzed about the applications he can talk about. He and his colleagues imagine sensors that track oil spills for a preset period and then melt into seawater, and cellphones with nontoxic circuits that biodegrade rather than poison landfills—and leave behind no memory cards for snoops to harvest for personal data. They also see a chest of medical devices: “smart stents” that report on how well an artery is healing; a pump that titrates medicine into hard-to-reach tissue; “electroceuticals” that fight pain with electrical pulses rather than drugs.

One benefit of “transience” in temporary medical implants is that it would spare patients the cost, hassle and health risks of a second surgery to retrieve the devices. But Rogers says the goal is less to replace existing in vivo technology—like pacemakers, cochlear implants or deep brain stimulators—than to bring electronics where they’ve never been before.

***

Not long ago, Rogers flew with his extended family to Malta, where his brother works as a video game designer. Rogers had spotted some flounder while snorkeling, and in the taxi from the beach to his brother’s house, his mother, Pattiann, the poet, marveled at the evolution of fish with eyes on their backs. “The various ways life has found to survive,” she said to her son, steering the conversation in a mystical direction. “Why is that?”

Her son was just as curious about the flounder, but for reasons that had little to do with metaphysics.

“It’s not the why,” he told her. "It's the how: How did they do it."

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Sabar_copy.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Sabar_copy.jpg)